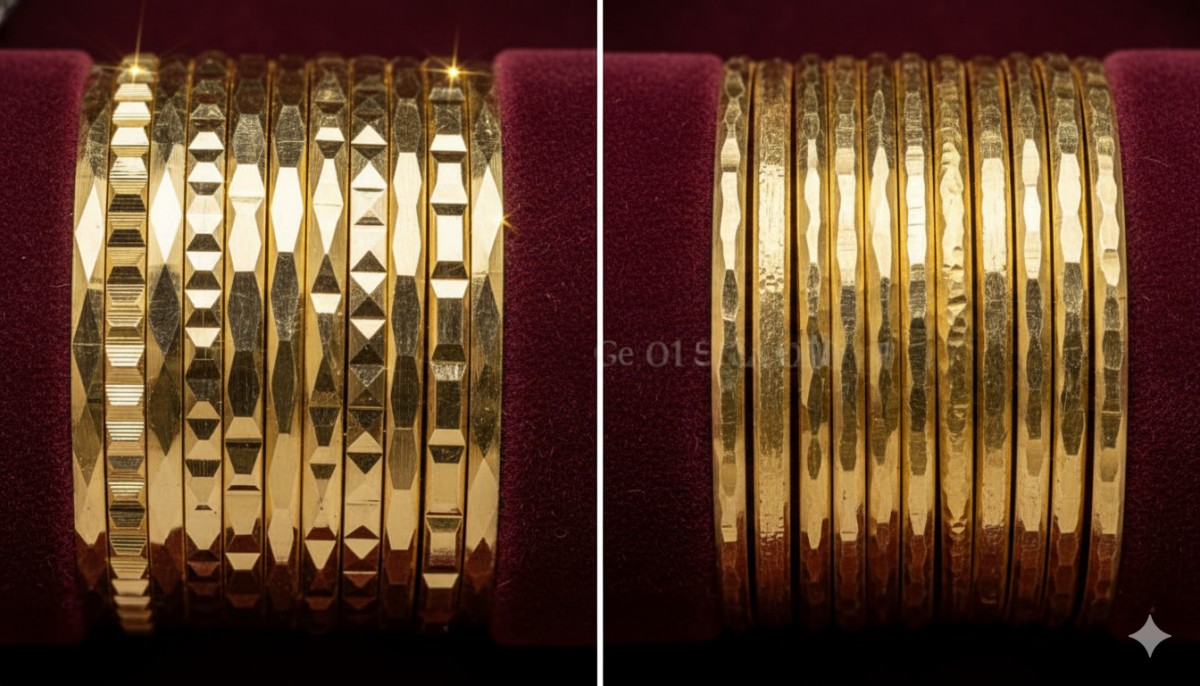

Walk into any jewelry store in India, and you will see two distinct types of gold bangles. On one tray, you have the “CNC” or “Machine Cut” bangles—they sparkle so brightly you’d swear they were studded with diamonds, even though they are plain gold. On the other tray, you have the Hand Made bangles—solid, heavy, with intricate wirework or “Rawa” (granulation) designs that look like they belong in a royal treasury.

The salesman will tell you the Machine Cut is “trendy and lightweight,” and the Hand Made is “traditional.” But he won’t tell you which one will survive your daily local train commute, your gym sessions, or 20 years of wear.

As a jewelry editor, I have seen thousands of broken bangles come in for repairs. I know exactly why they break. Today, we are settling the debate: Machine Cut vs. Hand Made Gold Bangles. Which one gives you the best value, and which one is actually durable?

Read more: Pastel Pink Meenakari on Gold

1. What Actually is “Machine Cut” (CNC) Jewelry?

When we say “Machine Cut,” we are usually talking about CNC (Computer Numerical Control) or Diamond Cut bangles.

- The Process: A solid gold pipe or sheet is fed into a high-precision robot. This robot uses a sharp diamond-tipped tool to “cut” facets into the gold.

- The Effect: Because the cuts are microscopic and precise, they reflect light like a disco ball. This is why these bangles shine more than any other type of gold jewelry.

- The Weight: Machines can work with very thin sheets of gold. You can get a broad, heavy-looking bangle in just 8 to 10 grams.

2. What is “Hand Made” Jewelry?

This is the old-school way. A Karigar (artisan) melts a gold bar, rolls it into a wire or sheet, and shapes the bangle by hand.

- The Process: They use hammers, files, and heat to solder pieces together.

- The Density: Because the gold is hammered repeatedly (a process called “work hardening”), the metal becomes denser and structurally tougher.

- The Weight: A handmade bangle needs a minimum thickness to be worked on. Usually, these start at 15 to 20 grams for a durable pair.

The Durability Showdown: Who Wins?

This is the most important part of your buying decision. Let’s break it down by real-world scenarios.

Round 1: Dent Resistance

- Machine Cut: LOW. Most machine-cut bangles in the market are hollow or made of very thin sheets to keep the price low. If you accidentally bang your wrist against a doorframe, a machine-cut bangle will likely dent. Once dented, the perfect geometric pattern is ruined.

- Hand Made: HIGH. Handmade bangles are typically solid or filled with Lac (wax). They are built to take a beating. Even if they get a small dent, it blends into the “organic” design and doesn’t look like a defect.

Round 2: Repairability

- Machine Cut: DIFFICULT. If a CNC bangle breaks or dents, it is a nightmare to fix. You cannot just “polish” it because polishing will erase the sharp diamond-cut facets that give it the sparkle. If a link snaps, soldering it leaves a visible black mark that breaks the perfect machine pattern.

- Hand Made: EASY. A local goldsmith can easily solder a handmade bangle. Because the design is manual, they can hammer it back into shape, buff it, and make it look brand new.

Round 3: The “Joint” Strength

- Machine Cut: These often don’t have joints (they are seamless pipes). This makes them strong against snapping, provided they are solid. If they are hollow, they can crush.

- Hand Made: The weak point is the “soldered joint.” If the artisan used low-quality solder, the bangle might snap at the joint after a few years. However, this is an easy, cheap fix (approx ₹200).

The Verdict: If you want a bangle you can wear 24/7 (while sleeping, bathing, cooking), Hand Made Solid Gold is the undisputed winner. If you want a bangle for office wear or parties that looks flashy but is treated with care, Machine Cut wins on aesthetics.

The Cost Analysis: Making Charges (Majdoori)

Here is where the Machine Cut bangles fight back.

Machine Cut Pricing

Since robots do the work, mass production is easy.

- Making Charges: Typically 8% to 14%.

- Wastage (VA): Lower, because machines collect all the gold dust efficiently.

- Resale: You lose less money on making charges when you exchange these.

Hand Made Pricing

You are paying for a human’s time and skill.

- Making Charges: Typically 15% to 25% (can go higher for antique/Nakshi work).

- Wastage: Higher.

- Resale: You lose a significant chunk of money on the high labor costs when you melt these down.

The “Glitter” Trap: A Warning

I often see clients choosing Machine Cut bangles because they “shine like diamonds.”

- The Pros: You get the “party look” without buying diamonds. It’s great for weddings.

- The Cons: That high-gloss shine relies on sharp edges. Over 2-3 years of daily wear, those sharp edges will rub against your clothes and skin, slowly becoming smooth. A Machine Cut bangle loses its sparkle over time. A Handmade bangle, which relies on design rather than polish, often looks better as it ages (developing a patina).

Styling Guide: When to Wear Which?

The Daily Stack (Office/Home)

Go for: Hand Made “Patla” or Solid Kadas. Look for simple, solid gold bangles with minimal soldering. They won’t snag on your saree or dupatta, and they won’t scratch your laptop while typing.

The Wedding Guest Look

Go for: Machine Cut / CNC. This is where you want maximum bling for minimum weight. You can wear a stack of 4 broad CNC bangles that look like 100 grams of gold but actually weigh only 40 grams. They catch the light beautifully in photos.

Technical Checklist Before Buying

Don’t just look at the design. Ask the jeweler these 3 questions:

- “Is this CNC bangle Solid or Hollow?”

- If they say “Hollow” or “Semi-solid,” walk away if you plan to wear it daily. It will crush.

- “What is the purity of the solder?”

- For handmade bangles, ensure the solder used at the joints is the same purity (22k) as the bangle. Otherwise, the joint will turn black over time.

- “Can this be resized?”

- Handmade bangles can usually be cut and resized. Machine Cut bangles with continuous patterns cannot be resized without ruining the design.

Conclusion: The Editor’s Choice

If I were buying bangles for my daughter to keep for 20 years, I would buy Hand Made. The craftsmanship has a soul, and the durability is unmatched. But, if I were buying bangles for myself to wear to my cousin’s wedding next month and I wanted to stay within a budget? I would buy Machine Cut.

The “best” bangle isn’t just about gold; it’s about your lifestyle. Are you a rough user, or are you gentle with your jewelry? Answer that, and you will know which one to buy.

Tell me: Do you prefer the mirror-shine of CNC or the antique look of handmade? Let me know in the comments!

Frequently Asked Questions (FAQs)

Do machine-cut bangles possess resale value

Yes, absolutely. The gold value remains the same (22k is 22k). In fact, because you pay lower making charges on machine-cut bangles initially, you actually lose less money when you resell them compared to expensive handmade pieces.

Why does my machine-cut bangle feel sharp?

This is a common issue. The diamond-cutting process creates tiny, sharp facets to reflect light. In low-quality finishing, these edges can be rough and snag on silk sarees or scratch a baby’s skin. Always run your finger over the bangle surface before buying to check for smoothness.

Can I wear hollow CNC bangles daily?

I strongly advise against it. Hollow bangles are made of thin gold sheets. The pressure of resting your hand on a table, holding a bag, or even clapping can cause dents. Once dented, a hollow bangle cannot be fully repaired.

How do I clean machine-cut bangles to keep them sparkling?

The Fix: Soak in warm soapy water for 10 minutes. Use a soft toothbrush to gently scrub the grooves. Do NOT use a polishing cloth vigorously, as it can smoothen the sharp facets and reduce the sparkle